Understanding the Significance of Well Seal Maintenance Ports

A well seal maintenance port might not be the flashiest part of your water well system, but it’s certainly one of the most important. Especially for those using Simmons’ 4-inch well seal maintenance ports, understanding how these components work can make all the difference in keeping your water clean, your system running smoothly, and your wallet happy.

Let’s dive into what makes these maintenance ports essential, how they work, and how to keep them in top shape.

Understanding the Role of a 4-Inch Well Seal Maintenance Port

Think of a maintenance port as the gateway to your well. It’s a small but critical opening that allows you (or your technician) to inspect, clean, or repair the well without disrupting the overall seal. Specifically, Simmons’ 4-inch maintenance ports are designed to:

- Simplify Inspections: Access the well casing for routine checks without hassle.

- Facilitate Repairs: Quickly fix or replace components, reducing downtime.

- Maintain Water Quality: Keep surface contaminants out and your water supply safe.

These ports are engineered to work with standard 4-inch casings, making them versatile and reliable for residential, commercial, and agricultural wells.

Advantages of Frequent Upkeep

Maintaining your well seal and maintenance port on a regular basis helps avoid issues rather than just solve them.

Here’s why you shouldn’t skip it:

- Prolong Equipment Life: Catching small issues early means fewer costly repairs and a longer-lasting system.

- Improve Water Quality: Keeping contaminants out ensures your water stays fresh and safe to use.

- Maximise Efficiency: A well-maintained system performs better, saving you energy and money.

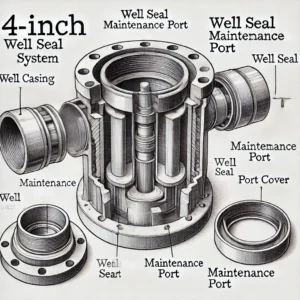

Visualizing the 4-inch Well Seal Maintenance Port

Here is a diagram illustrating a 4-inch well seal maintenance port system. It highlights the key components, including the well casing, well seal, maintenance port, and port cover, in a cross-sectional view for clarity. Let me know if you’d like any adjustments or further details!

Anatomy of a Well Seal Maintenance Port

Here’s a breakdown of the key components of a 4-inch well seal maintenance port and how they work together:

- Well Casing:

The protective pipe that lines the well, providing structural support and preventing soil from collapsing into the borehole. - Well Seal:

A watertight gasket, usually made of rubber or plastic, that fits snugly around the casing and pump wiring. It’s the first line of defense against contaminants. - Maintenance Port:

A dedicated access point within the seal for tools, testing equipment, or disinfection treatments. - Port Cover:

A cap or plug that keeps the maintenance port sealed when not in use, shielding it from dirt, debris, and damage.

How to Maintain Your Simmons Well Seal Maintenance Port

Maintaining your well seal and its maintenance port doesn’t have to be complicated, but it does require attention to detail. Here’s how:

1. Locate the Port

Find the maintenance port on the well seal, typically a threaded fitting near the top of the casing.

2. Inspect the Port

Remove the port cover carefully to avoid damaging threads or seals. Use a flashlight or borescope to check for cracks, debris, or corrosion inside the casing.

3. Clean the Area

Clear away dirt or mineral deposits using a soft brush and a non-corrosive cleaner. Keeping the area clean ensures the port functions properly and extends its lifespan.

4. Replace Worn Parts

If the seal or cover shows signs of wear, replace it promptly. Always use manufacturer-approved parts, like those from Simmons, for a proper fit and long-lasting performance.

5. Secure the Cover

Once maintenance is complete, tighten the port cover securely to prevent contamination or leaks.

Troubleshooting Common Issues

Even with regular maintenance, issues can arise. Here’s how to tackle the most common ones:

- Clogged or Damaged Ports:

Mineral buildup can block the port, making it hard to access. Use a small wire brush or cleaning solution to remove obstructions. If the port is damaged, it may need to be replaced. - Leaky Seals:

Over time, seals can crack or lose their watertight properties. Inspect regularly and replace seals as needed to prevent contamination. - Water Quality Problems:

If your water is cloudy or tastes off, it could indicate a breach in the seal. Test the water and consult a professional for repairs if contamination is detected.

Why Choose Simmons 4-Inch Well Seal Maintenance Ports?

Simmons stands out in the water well industry for good reason. Their 4-inch maintenance ports are designed with:

- Top-Quality Materials: Built to last, these ports can withstand harsh environments and heavy use.

- Ease of Use: Simple installation and maintenance make them a favorite for professionals and DIYers alike.

- Versatility: Compatible with a wide range of well systems, Simmons ports are a smart choice for nearly any setup.

Specific Maintenance Schedule

To keep your well seal and maintenance port functioning optimally, follow this recommended schedule:

- Monthly Visual Inspections:

- Check the area around the well for signs of damage, leaks, or debris buildup.

- Ensure the port cover is securely in place to prevent contamination.

- Biannual Maintenance Checks:

- Open the maintenance port and inspect the well casing, seal, and interior for corrosion, cracks, or blockages.

- Clean the port and surrounding components to remove dirt or mineral deposits.

- Annual Professional Inspection:

- Hire a licensed well technician to perform a thorough assessment, including water testing, seal integrity checks, and system efficiency evaluation.

- Seal Replacement Every 3-5 Years (or as needed):

- Replace the well seal if there are signs of wear, cracking, or reduced effectiveness in maintaining a watertight barrier.

Local Regulations

Water well maintenance and testing requirements can vary depending on your location. Be sure to:

- Consult local health departments or regulatory bodies for specific well maintenance guidelines and water quality standards.

- Stay informed about testing frequencies for contaminants like bacteria, nitrates, and heavy metals, which are often mandated by local authorities.

- Keep records of inspections and maintenance to comply with any reporting requirements.

Emergency Procedures

In case of a well seal emergency, such as a leak or contamination, take the following steps:

- Stop Using the Water Immediately:

- Avoid consuming or using water from the well until the issue is resolved and the water is tested.

- Seal the Contaminated Area:

- If possible, secure the maintenance port and surrounding area to prevent further intrusion of contaminants.

- Contact a Professional:

- Call a licensed well technician to inspect the well and assess the damage.

- If contamination is confirmed, the technician may recommend shock chlorination or other disinfection methods.

- Test the Water:

- Conduct a water quality test after repairs to ensure the water is safe to use.

- Prevent Future Issues:

- Review and enhance regular maintenance practices to avoid similar emergencies in the future.

By adhering to a specific maintenance schedule, staying compliant with local regulations, and knowing how to handle emergencies, you can ensure the long-term health and functionality of your well system.

Final Thoughts

Your well is more than just a source of water—it’s an investment in your property and your health. By prioritizing regular maintenance and using trusted components like Simmons’ 4-inch well seal maintenance ports, you can ensure your system remains efficient, durable, and safe for years to come.

For more complex repairs or inspections, don’t hesitate to call a licensed well technician. And remember, a little upkeep today can save you a lot of trouble tomorrow.